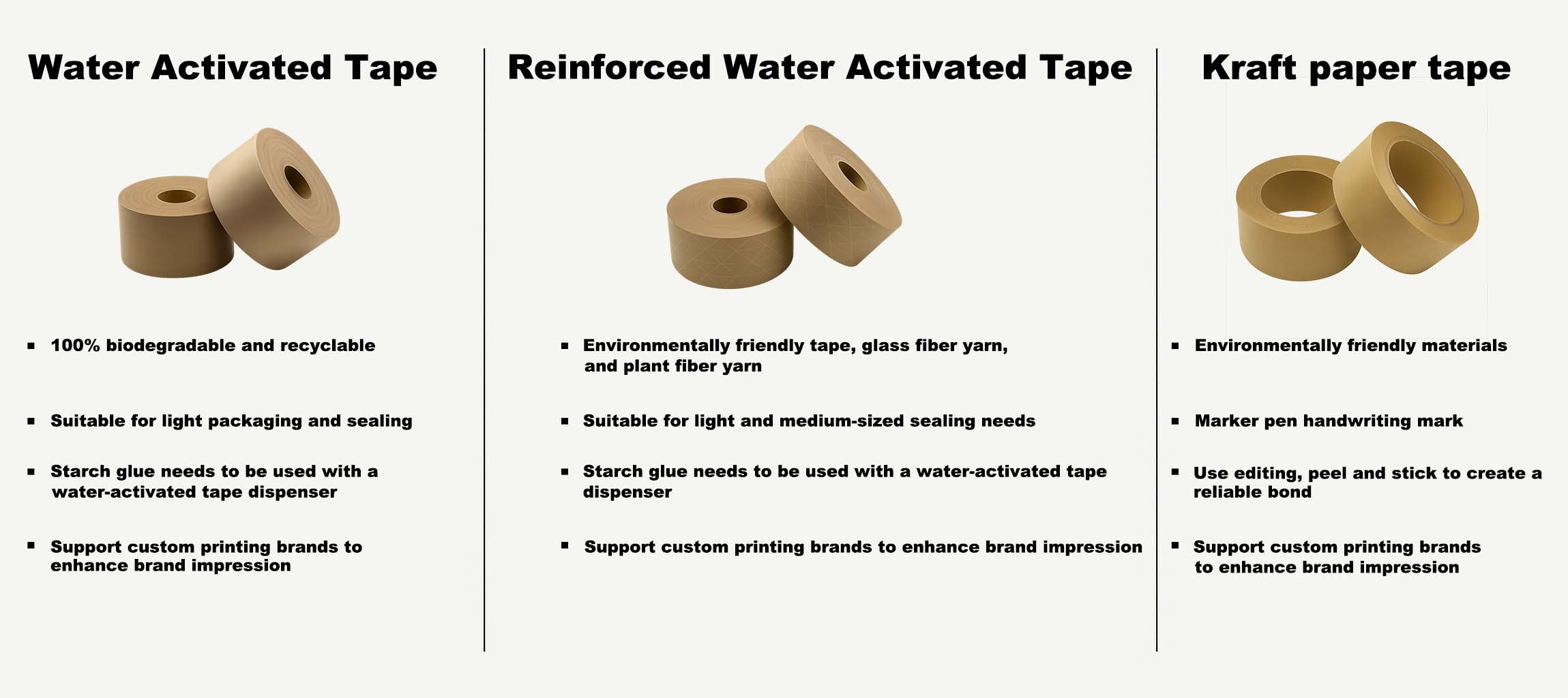

What is the difference between water-activated tape and kraft paper tape? Both water-activated tape and kraft paper tape are used for sealing cartons, especially in packaging applications that emphasize environmental sustainability or brand promotion. While they may appear similar at first glance, their functions differ slightly, and they are made from different materials. Understanding these differences can help ensure you select the right tape for your packaging needs. Although both are paper-based and eco-friendly, the key differences lie in the type of adhesive and the application method. What is Water-Activated Tape? Water-activated tape, commonly referred to as gummed tape, is a carton-sealing tape that requires water to activate its adhesive. It is primarily made from kraft paper and coated on one side with a starch-based adhesive. Once moistened, the adhesive bonds firmly to the carton surface, creating a tamper-evident seal. This tape is widely used for sealing lightweight to medium-weight cartons, particularly for export or long-distance transportation, as the adhesive penetrates the carton surface, forming a strong and durable seal.reinforce water-activated tapes also incorporate fiberglass yarn or Plant fiber yarn, enhancing tensile strength and security. Reinforced water-activated tape contains embedded fiberglass yarns or Plant fiber yarn, which improve its durability and tear resistance. It is a reliable choice for heavy or high-value packaging that requires additional strength. It has a clean and simple appearance, making it suitable for standard carton sealing. While it provides strong adhesion, it is typically better suited for lighter-weight cartons. Water-activated tape requires a tape dispenser equipped with a water reservoir to moisten the adhesive. These dispensers ensure consistent activation of the adhesive, allowing users to seal cartons quickly and efficiently. For higher efficiency, electric water-activated tape dispensers can be used. The standard widths for water-activated tape are 70 mm and 72 mm. JL3 offers custom width options based on specific application requirements. What is Kraft Paper Tape? Kraft paper tape is a pressure-sensitive tape made from kraft paper. Unlike water-activated tape, it does not require water to adhere and can be applied manually or with a tape dispenser from JL3. It provides a simple and sustainable solution for sealing lightweight to medium-weight cartons. For businesses seeking an eco-friendly tape that can also be printed with brand logos, kraft paper tape is an ideal choice. It blends seamlessly with brown cartons, has a writable surface, and is convenient for labeling or imprinting. Kraft paper tape mainly comes in two types: hot-melt adhesive and water-sensitive adhesive. The hot-melt type offers strong adhesion and excellent initial tack, while the water-sensitive type provides superior resist...

Learn More English

English Deutsch

Deutsch español

español العربية

العربية 中文

中文

IPv6 network supported

IPv6 network supported